Stainless steel mesh cages have a long association with

intertidal ecology and were a key part in some of the early studies that

created the field of experimental ecology. The early work of Joe Connell

(1961) is responsible for introducing most people to the use of mesh

cages for manipulating the densities of predators and grazers. Connell

used 22 gauge wire mesh with 8 squares per inch, formed into 6"x6" square

cages, to exclude predatory whelks from patches of barncles. All of

your favorite intertidal ecologists have probably used mesh cages at

some point in their careers, and there are a wide variety of cage styles

and construction techniques out there. All of these different cages

probably worked well, but I'm going to outline the single best method for

making cages that do the job and are durable enough to someday hand down

to your grandchildren.

Cages deployed in the field

at Hopkins Marine Station

Materials

Cages deployed in the field

at Hopkins Marine Station

Materials

There is only one choice of material for making really durable

cages: stainless steel. Plastic mesh works to a certain extent, but

you'll have a hard time building a cage that will hold together under

vigorous wave action out of only plastic. Regular steel obviously rusts,

even when youbuy the plastic-coated stuff. If you need to build three

dimensional structures to mount on the rocks in wave-beaten areas, and

you need them to last for more than just a few months, skip over plastic

or other materials and step up to stainless steel.

Stainless steel mesh is available in a wide variety of sizes, as it

has many uses in manufacturing. We'll base this instruction set on

the assumption that you'll be ordering your stainless mesh from

McMaster-Carr. McMaster-Carr

specifies dimensions in inches rather than SI units, so this tutorial

will abide by their conventions. You can search through the various mesh

types by entering "

wire mesh"

into the search field at McMaster. Then choose either "

woven wire cloth" or "

welded wire cloth". The

differences are explained below.

There are two alloys of stainless steel mesh usually offered, type

304 and type 316. Type 304 is preferrable for our uses, as it is nearly

half the price of type 316. Type 316 is somewhat more resistant to

corrosion by harsh chemicals, but unless you're doing your predator

exclusions in some sort of sulfur-rich hot springs, type 316 will be

overkill. Stick with type 304, which will not rust even after years in

the field.

Dimensions

The size of the mesh that you use in your cages is obviously set by

the minimum-sized organism you need to contain or exclude. If you're

keeping out grazing limpets for example, you want to consider how small a

shell size will fit through your mesh. Realistically, you'll have to

balance the animal-filtering ability of your mesh versus the impact that

the mesh will have on water flow and shading of the substrate under

the cage. Keeping out the most voracious adult-sized grazers or

predators will often be sufficient, and taking some care to open the cage

to remove smaller interlopers every few weeks will likely be enough

to remove the effect of that animal on the experimental plot. With

this trade-off in mind, you can choose a mesh size.

Mesh is sold by a variety of dimensions. You can choose mesh based on the

size of the openings in the mesh. An equally common method for shopping

is to choose mesh by the number of squares-per-inch (i.e. 1x1,2x2, 4x4).

A 4x4 piece of mesh has 4 squares per 1" of linear dimension.

You will also need to specify the thickness of the wire that makes upthe

mesh. A good all-around wire diameter is 0.047". The 0.047" size holds up

well for month or years, and is still thin enough to be workable when

you're constructing the cages.

Mesh style

There are two categories of stainless steel mesh that we will

consider: Woven wire cloth and welded wire cloth.

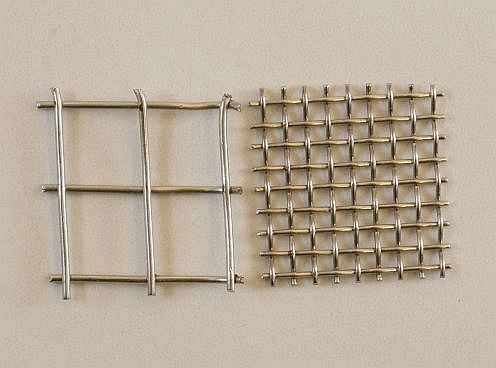

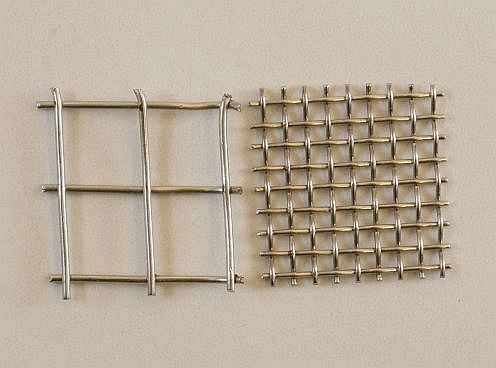

Welded wire cloth mesh on

the left, woven wire cloth mesh on the right

Welded wire cloth mesh on

the left, woven wire cloth mesh on the right

Woven wire cloth is available in sizes from 2x2 through 16x16

and smaller. Welded wire cloth is only available in larger sizes, from

1x1through 4x4. If you need to exclude very small organisms, you will

end up using woven wire mesh in sizes from 4x4 through 8x8 or smaller.

If you are going to build large cages with large holes to only keep

out large organisms like bird and fish, you will need to use the welded

mesh in sizes up to 1x1 (~1" opening).

Which style is better?

As mentioned above, for large-opening cages (>1/2" openings), you will be

better off using welded wire mesh, and also using a larger, stiffer wire

diameter (0.063" or 0.08"). The stiffness of a cage is tied to the mesh

opening size and the mesh style (welded or woven). When you

have relatively few strands of wire making up the cage (1x1, 2x2 cages),

a woven mesh cage would not be strong enough to withstand flexing

under breaking waves, as it would simply fold over. A welded wire cage

will be inherently stiffer.

The stiffness of welded wire comes with some costs though. It is

more difficult to make complicated shapes with welded wire,

particularly circular features. Welded wire doesn't move and flex as well

as woven wire when you're bending it, so the welded mesh will either

start popping apart at the welds, or just get kinked. Welded mesh is

best reserved for simple slab-sided square cage styles where only

simple bends are involved, or perhaps hexagonal fences. Welded wire cages

also fatigue after time due to their stiffness. A cage sitting in the

field getting hit by a wave every 10-15 seconds during high tide for

months at a time will undergo a huge number of flexing cycles, which will

cause welds to start to fail and the integrity of the cage to fall apart.

This is one reason for using larger wire diameters in cages made with

larger mesh sizes, as it stiffens the cage and reduced the amount of

flexing with each wave, reducing the amount of fatigue in the structure.

Woven wire mesh is a good choice for cages with smaller openings

(3x3, 4x4, 8x8 etc). Woven mesh is easier to bend and form into

complicated shapes such as circles. Woven mesh is also capable of being

woven together at corners and seams, since you can leave longer pieces of

wire hanging off your cuts that can then be woven. When you get into the

very small mesh openings (6x6, 8x8 etc), welded wire mesh, if it

was available, would be horrible to work with. At these smaller mesh

sizes,the structural integrity of the cage is good because there is so

much material in the structure. The completed cage can flex a little

with each wave, but there are no welded joints to fatigue and fail over

time. Woven wire mesh cages have no trouble standing up on their own in

mesh sizes up to 4x4.

Construction

Cages, fences, cage controls and other structures come in a

variety "standard" shapes and sizes. Some people prefer circular plots,

others like simpler square or rectangular plots. All cages need some sort

of flange to allow them to be bolted down to the substrate. This takes

the form of a section of mesh bent out horizontal around the bottom edge

of the cage. This flange should be >1.25" wide to give you some leeway

in positioning the cage over holes in the rock. My cages usually have

a 1.5" wide flange around the bottom. Stainless steel lag bolts get

pushed through the mesh flange and screwed into plastic masonry anchors

in the rock.

For all cage styles, try to make the whole structure out of one piece

of mesh rather than trying to tie multiple pieces of mesh together into

a structure. Structures bent up from one piece of mesh will be

stronger than a pieced-together mess.

To cut the mesh, get a pair of tin snips. Tin snips come in

straight, left, and right cutting styles. Any style of tin snip will be

fine for this job. Straight-cutting tin snips are show on the right in

the picture below.

Vise-grips on the left,

tin snips on the right

Vise-grips on the left,

tin snips on the right

If you have access to a jump shear in your shop, you can make

large straight cuts quickly. This can be useful for cutting your big roll

of mesh into individual pieces that eventually become the cages. You

will still need the tin snips to make smaller cuts in the mesh for

bending. Don't try cutting the mesh on a band saw, it will just get

messy.

For making bends in the mesh, the best option is to find a

sheetmetal brake in the shop. This will let you make most of the bends

easily. If you don't have access to a brake, there are other ways to bend

the mesh. The most burly method is clearly to bend it using your teeth.

If you aren't up to that, I recommend finding a sturdy table with a top

that sticks out a little ways. Using some c-clamps and a long piece of

wood or metal, you can clamp one part of the mesh to the table, and then

bend the other portion over the edge of the table. To get nice crisp

bends you can take a hammer to the mesh to make sure it bends sharply at

the edge of the table.

Bending mesh over the edge of

a work bench

Bending mesh over the edge of

a work bench

The round fence shown below was bent in this manner. The entire

long strip of mesh was clamped to the edge of a workbench so that half of

the mesh was sticking out. I then went along with a hammer and pounded

the mesh down until it was bent at 90 degrees. After the entire piece

was bent I took it out and put the circle bend in it. The cuts around

the flange of the fence are spots where I had to cut the mesh to allow me

to get the circular bend in the mesh. The fence is then closed with

zipties, or you can use any long pieces of wire sticking out the ends

of the mesh to weave the two ends together.

A 20cm diameter fence made

from one long piece of mesh

A 20cm diameter fence made

from one long piece of mesh

The square cage below was built in a slightly different fashion. Thecage

is 10x10cm, so it is fairly small. I made the bends in this cage

by clamping it in a bench vise and bending the mesh over. The initial

piece of mesh was cut to resemble a big

+sign.

Each arm of the

+ was bent down

at 90 degrees relative to the center, and then each arm was bent out

horizontal to form the flange. The four sides of the cage meet in the

corners. I purposely left the wire mesh edges long when I cut the

+ shape. These long ends could then be

weaved through the adjacent pieces of mesh to close the corners. Weaving

the mesh together like this produces a very strong and stiff cage that is

also fairly well sealed against animals getting in and out.

A 15x15cm full cage

for excluding whelks

A 15x15cm full cage

for excluding whelks

Excess wire on ends of mesh

is folded over adjoining wire to tie the two sections together

Excess wire on ends of mesh

is folded over adjoining wire to tie the two sections together

The weaving process makes use of the other pair of pliers pictured

with the tin snips above. These are small needle nose Vise-Grip pliers.

I prefer these to normal pliers because they allow you to lock on to

the wire while you're bending it, relieving you have having to squeeze

as hard as you can the whole time. After weaving and bending a few

hundred wires for a set of cages, your hands will thank you.

Leaving extra wire hanging

off the ends of cut mesh

Leaving extra wire hanging

off the ends of cut mesh

If you are using woven mesh, the ends of the mesh pieces will have

loose ends sticking out. After time those loose ends can start to fray

and pieces of wire can pull out. This often happens around the edges

of flanges. The solution is to clean up the cut edges by bending the

loose wire back over on itself, wrapping it around the wires

running perpendicular to it. In the image below I have bent the loose

wires around the corner over and under the wire that crosses them. This

makes it impossible for the mesh to come apart, and has the added bonus

of making the cage safer to handle, as you won't get poked by the cut

ends of wire.

Loose ends of wire are

folded over the crossing wire to tie the edges together

Loose ends of wire are

folded over the crossing wire to tie the edges together

The other option is to take a material such as Z-spar epoxy putty

and form it over the exposed edges of the wire mesh. This will help hold

the wires together, and makes the edges smoother for handling. The

down side to this method is that epoxy putties are brittle, so when you

need to bend the cage around features in the rock you make end up

cracking the putty.

Most of the above info pertains to woven mesh cages. When using

welded wire mesh, the assembly process is somewhat simpler. You do not

need to bend over the loose edges, as the welded wire will not unravel.

You would still do well to leave extra wire sticking out at cage seams

so that you can weave the seams together for a tight fit. This also

helps strengthen the cage.

Mounting cages in the field

Mounting cages in the field

Cages should be mounted using the standard plastic masonry anchors

and 1/4" stainless steel lag bolts.

Masonry anchors are available from McMaster-Carr, search for part

number 95482A145. There are other lengths available besides the part

number given here. A common lag bolt from McMaster-Carr is part

number 92351A544, and again, there are multiple lengths available. A

larger list of useful field equipment and pictures can be found here:

https://www.lukemiller.org/journal/2005/05/field-equipment.html

In the larger mesh sizes you can simply slip the bolt through the

mesh openings and screw it into the rock. For smaller mesh sizes (6x6,

8x8), you will need to punch a hole through the mesh to get the screw

through. My favorite technique is to just take the hammer drill that you

use to drill holes for the blue anchors and drill through the mesh. I

usually do this out in the field at the same time that I'm installing the

blue anchors, so that I can easily line up the holes.

For all mesh sizes, you will need some sort of washer or plate to put

onthe lag screw to help spread the load on the mesh. The heads of the

lag screws are fairly small and will pull through the mesh after a while.

I use either large stainless steel washers, or pieces of plastic cut

into 3"x1" strips with a >1/4" hole drilled through the middle. These

help spread the load over more the mesh, and also help keep the mesh

from folding up and allowing animals to sneak in.

For washers, a good example would be McMaster-Carr part number 90313A109.

You can also simply search for "washer" at McMaster and choose a size

that suits your budget.

If you're going to use plastic pieces instead of washers, drill the

hole with at least a 17/64" drill bit. This will give you enough play to

get the 1/4" lag bolt through.

One or two bolts for each side of a cage will be sufficient to hold

it down to the rock. The image below shows a 4x4 mesh cage bolted to

the rock using both stainless steel washers and plastic pieces.

A cage deployed in the field

A cage deployed in the field

That's more or less it for making cages. There are plenty of

variations on this basic theme depending on what you're trying to

accomplish.

Some other thoughts:

One common modification for cages that you need to open for censusing

is to leave the top of the cage open (i.e. make a fence) and zip-tie

a piece of plastic mesh over the top of the cage to seal it. The zip

tiescan be cut and replaced each time you need to access the

cage. Alternatively you can unbolt the cage from the rock at census time.

If you're doing point-contact counts in small plots, it will probably

be easiest to simply unbolt the entire cage for counting.

For instances where you're dealing with small organisms that crawl

along the rock surface, some people sandwich strips of neoprene

rubber (wetsuit material) between the cage flange and the rock.

Cages will eventually get algae settling on them. This can be detrimental

to your experiment, so you may occasionally need to clean the cages. Some

people use stiff wire brushes to clean the cages. A more effective method

is to kill the algae either by boiling or with direct flame. Chris Harley

introduced me to the idea of bringing a Colemanstove out into the field

and heating up a big wok full of water. Hot enough water will kill the

algae and it will slough off during the next tide. A propane torch

applied directly to the algae also works well.

Cage controls are a messy subject, and there are several styles

outthere. All of them have their downsides and introduce unwanted

artifacts that differ from the full cage treatment. Cage controls all

have someside or sides open so that the organisms of interest can move

in and out. Some cage controls concentrate solely on mimicing the

shading effect of the full cage, so they might have a piece of mesh held

up on 4 posts. Other cage controls are concerned with also mimicing the

effects of the cage on water flow, so they only have small sections of

the sides removed, or perhaps two full sides removed.

A style of cage control with two

open sides

A style of cage control with two

open sides

The choice of cage control is up to you, but consider what factors

you think are most likely to cause experimental artifacts when caging

a plot, and design your cage control to *properly* mimic those effects.

Luke Miller

April 2006